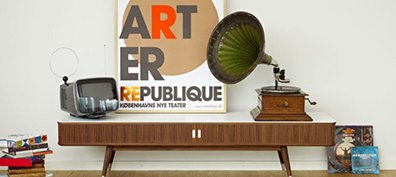

Purchasing a sofa is far from an everyday event. When you do find yourself in such a situation, you probably would expect the sofa to last you through several decades. If you are now starting to wonder what exactly goes into a first-rate sofa, the craftsmen at Eilersen are the people to ask. These miracle workers have been refining the art of making people sit comfortably for 120 years. Naturally, they would know how to craft a high-quality sofa more than most.

This article is the first in the series of three articles on the materials that make up an Eilersen sofa and how they will contribute to your (and your loved ones’) seating comfort in the years to come.

Quality Pinewood

The frameworks of all Eilersen sofas are made of high-quality pine. This allows for flexibility, lightness and most critically, durability. Once loggers fell these trees, they would be oven-dried and removed only when it has achieved a moisture content of 8-10%. The slower and steadier the growth of a tree, the sturdier the harvested wood will be.

For Eilersen, this led to a preference for Scandinavian pines that originate from north of the 60th parallel. There, the colder climate promotes slow growth, leading to fewer knots and reduced tension in the wood. The advantages of these are, lesser waste and a sofa frame that does not stretch or turn no matter what.

Stronger Joints

Eilersen believes that the Danish-designed spiral grooved dowels are the best (in the world) in ensuring quality joinery in their sofas. When these dowels are pressed into the beech wood, the width will be reduced by 0.1mm. Together with a precisely measured chamfer, the spiral dowel allows the glue to cover the widest possible surface area. Then, when pushed into the hole, the glue moisture expands the dowel by 0.1mm, paving the way to the firmest joint possible.

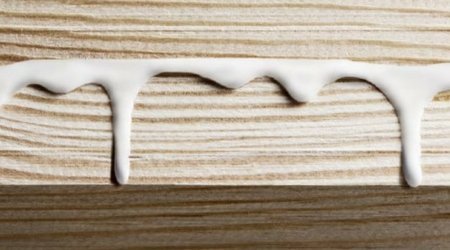

Perfect Adhesives

Too much of something is always better than too little of it. Critical joints in Eilersen sofas should show ‘curtains’ of excess glue, which proves that the inner surfaces are completed layered with the adhesive. The glues used are also water-based and contains a resin that slowly hardens over the span of a day. This means the frames must be level as they harden. These adhesives are boil-dry-freeze tested and carry the Greenguard Gold Certification.

Increased Flexibility & Sturdiness

To align the lengthier sides of the sofa framework, a seat bracket is used. Eilersen uses steel or solid beech wood in order to ensure that the sofa frame maintains its strength and suppleness. Other manufacturers of modern sofas consider this crafting step to be irrelevant. Eilersen, on the other hand, does not compromise on quality.

Clean Lines

Masonite is a type of wood fibre hardboard that is both high-density and waterproof. Just like other materials made from wood, Masonite contains formaldehyde. However, Eilersen ensures that they adhere to the N-0 quality with the lowest possible content. Three millimeter-thick boards are used in the sofas to stabilize and cover inside backs, armrests and frames. The use of top-quality Masonite ensures that your sofa will retain its shape.

Secure Staples

In an Eilersen sofa, no detail was left unattended to. This goes for the staples as well. Depending on the function the staples would play, staples of three different sizes are used in the construction of these sofas. For added security, some staples will be glue-coated, ensuring permanent and instant fixture.

At Eilersen, the craftsmen strive for nothing less than perfection. Visit our furniture showroom to experience the luxurious comfort and uncompromising quality of our Eilersen sofa collection.

Danish Design | Authentic Designer Furniture

Danish Design | Authentic Designer Furniture